To correctly manage all the factors that can influence the outcome of the operation of cooling tower or steam boiler operation requires considerable technical knowledge, the right tools, and the skills to use them. A complexity that requires ability, experience and aptitude.

The computerised predictive water modelling software package from ZI-CHEM is arguably the most advanced practical application software for industrial evaporative cooling towers and boilers available in the market today in this region.

When operated by trained technicians, these computer model design programs allow accurate prediction of all critical parameters that can influence the outcome of a water management program, and allow for the selection of the most effective program at the most efficient cost.

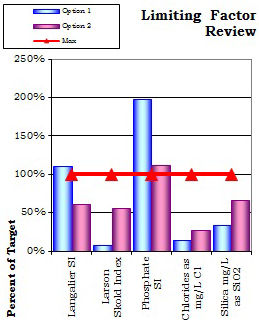

One of the most important components of the ZI-CHEM water design model for open cooling tower systems is the “Limiting Factor Review”. This is the first primary step in determining which several critical competing objectives will “Limit” the efforts to minimise cost.

Data from plant operating conditions is entered into the model, including makeup water analyses, makeup water flow, recirculation rates, volume, maximum skin temperature and supply/return temperatures. Targets for critical performance criteria are also entered for various types of scale deposition and corrosion are also added. The levels of these are often determined by the performance capabilities of the chemical treatment program that is selected.

The model then shows which factor will be reached and/or exceeded first. The user can then adjust various variables to ensure that all variables are controlled within target range and the most efficient program is selected.

This computerized model can also be used for troubleshooting existing systems, and has frequently been used to accurately identify the cause of major plant failures and the successful design of alternative programs to prevent a re-occurrence in the future.